Modular transport solutions: Alusic and Modu through Sitalu

Sitalu, Gold Partner of Alusic and strategic distributor of Modu in Spain, offers advanced modular transport solutions tailored to the needs of modern industrial automation. Through the brands Alusic and Modu, Sitalu provides transport systems designed to increase operational efficiency and productivity across various industrial sectors.

Featured conveyors from Modu:

Plastic hinge conveyor Modu MS2 / 65mm

The Modu MS2 is a conveyor system with a 63 mm thermoplastic chain and an aluminum frame, suitable for sectors such as pharmaceuticals and automotive. It supports up to 200 kg with an operating temperature of -10°C to 60°C and can achieve a speed of 50 m/min.

Plastic hinge conveyor Modu ML2 / 145mm

Plastic hinge conveyor Modu MX2 / 315mm

The Modu MX2 conveyor system uses a 220 mm plastic chain, ideal for applications in industries such as pharmaceuticals, chemicals, automotive, food, electronics, paper, and optics. This versatile system adapts to a wide range of industrial transport needs.

Modu MT2 Modular Belt Conveyor / 315mm

The Modu MT2 conveyor system features a thermoplastic belt that is 315 mm wide with an aluminum frame, suitable for various industries such as pharmaceuticals, automotive, food, and electronics. It supports a total load of up to 300 kg, operates between -10°C and 60°C, and reaches speeds of up to 50 m/min. This robust system can handle maximum working tensions of 1500 N, even in configurations with curves.

Modu MR2 Modular Belt Conveyor / 438mm

The Modu MR2 conveyor system, with a thermoplastic chain that is 438 mm wide and an aluminum frame, is ideal for various industries such as pharmaceuticals, automotive, and food. This robust system supports a total load of up to 300 kg, operates within a temperature range of -10°C to 60°C, and achieves a maximum speed of 50 m/min. Designed to handle tensions of up to 1900 N without curves and 1800 N with curves, the MR2 ensures efficiency and reliability in product transportation.

Modu MF2 Modular Belt Conveyor / 585mm

The Modu conveyor system with a 585 mm wide chain and aluminum frame is ideal for industries such as pharmaceuticals and automotive. It supports up to 300 kg, operates between -10°C and 60°C, and reaches speeds of up to 50 m/min. Capable of handling tensions of up to 2200 N, this conveyor is perfect for demanding applications.

The Modu MS2 is a conveyor system with a 63 mm thermoplastic chain and an aluminum frame, suitable for sectors such as pharmaceuticals and automotive. It supports up to 200 kg with an operating temperature of -10°C to 60°C and can achieve a speed of 50 m/min.

The Modu MX2 conveyor system uses a 220 mm plastic chain, ideal for applications in industries such as pharmaceuticals, chemicals, automotive, food, electronics, paper, and optics. This versatile system adapts to a wide range of industrial transport needs.

The Modu MT2 conveyor system features a thermoplastic belt that is 315 mm wide with an aluminum frame, suitable for various industries such as pharmaceuticals, automotive, food, and electronics. It supports a total load of up to 300 kg, operates between -10°C and 60°C, and reaches speeds of up to 50 m/min. This robust system can handle maximum working tensions of 1500 N, even in configurations with curves.

The Modu MR2 conveyor system, with a thermoplastic chain that is 438 mm wide and an aluminum frame, is ideal for various industries such as pharmaceuticals, automotive, and food. This robust system supports a total load of up to 300 kg, operates within a temperature range of -10°C to 60°C, and achieves a maximum speed of 50 m/min. Designed to handle tensions of up to 1900 N without curves and 1800 N with curves, the MR2 ensures efficiency and reliability in product transportation.

The Modu conveyor system with a 585 mm wide chain and aluminum frame is ideal for industries such as pharmaceuticals and automotive. It supports up to 300 kg, operates between -10°C and 60°C, and reaches speeds of up to 50 m/min. Capable of handling tensions of up to 2200 N, this conveyor is perfect for demanding applications.

Modular transport solutions from Alusic distributed by Sitalu

Alusic, represented in Spain by Sitalu, offers a complete range of modular transport solutions to adapt to various industrial environments. From basic material handling to specialized applications, Alusic provides customizable and efficient transport systems and pallets.

Alusic also offers a complete selection of accessories to customize and enhance transport systems, including side containment guides, sliding profiles, and guide supports, ensuring that each system is efficient and tailored to the specific needs of the customer.

Conveyor Belts

Alusic’s conveyor belts are versatile solutions designed to adapt to a variety of industrial applications. Available in different series, each with specific features:

- Series 20: 20 mm diameter roller, ideal for light operations.

- Series 30: 30 mm diameter roller, for medium loads.

- Series 50 and 1000 Single beam: 50 mm diameter roller, suitable for heavier loads.

- Series 95: 95 mm diameter roller, for the most demanding applications.

Belt with slope change Series 830

The Series 830 is specially designed to handle changes in slope within transport lines. With three basic structures (831, 832, and 833), this system allows for flexible and adaptable configurations, incorporating accessories such as hoppers and ramps to optimize transport in environments with height variations.

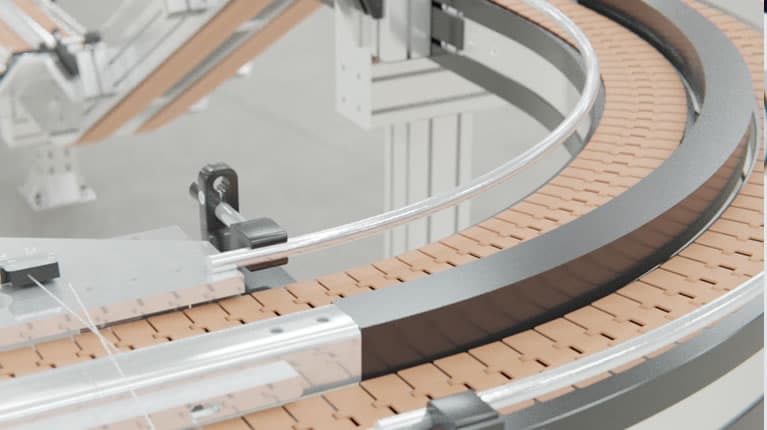

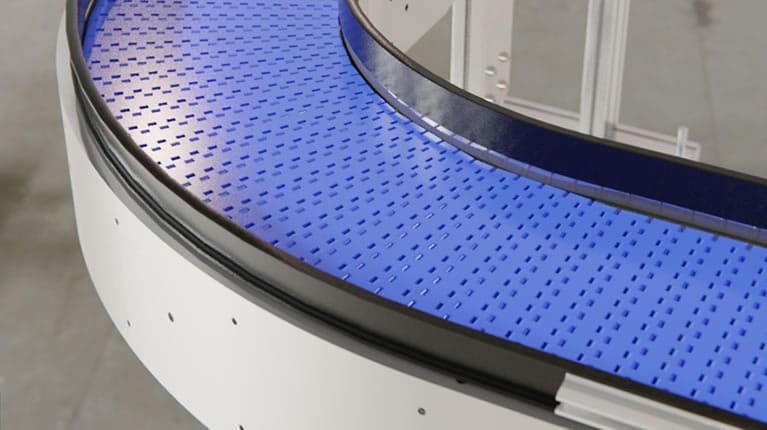

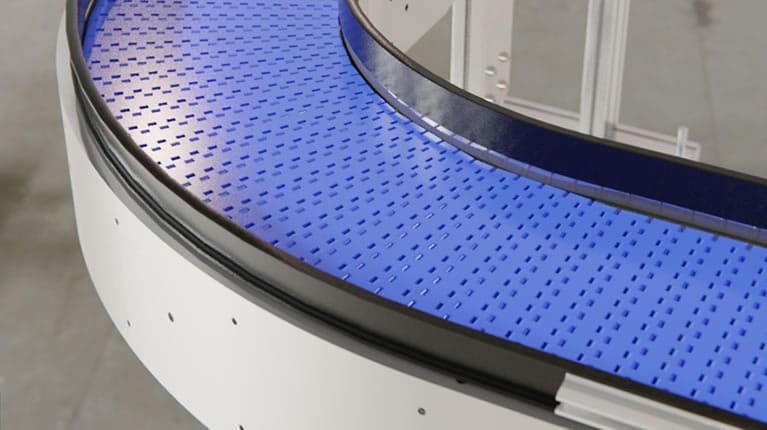

Hinged Belt Conveyors

Alusic offers hinged belt conveyors with five different chain widths, ranging from 82.5 mm to 304.8 mm, available in both plastic and steel. These systems are ideal for applications that require durability and flexibility, with curves available as standard for the smaller models, facilitating integration in compact spaces.

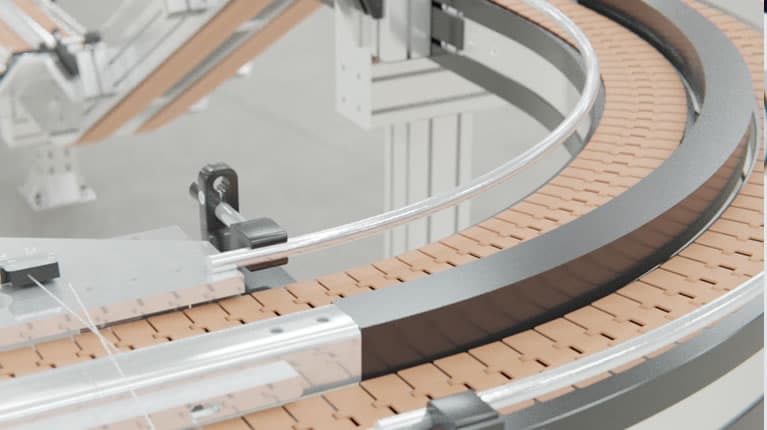

Modular chain conveyors

Alusic’s modular chain conveyors feature plastic chains in two widths: 152 mm and 250 mm. These systems have composable beams and offer standard 90° and 180° curves, making them extremely flexible to fit any production layout.

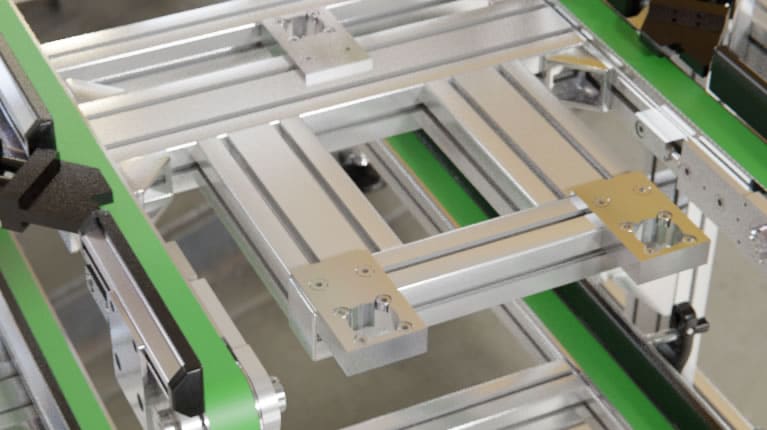

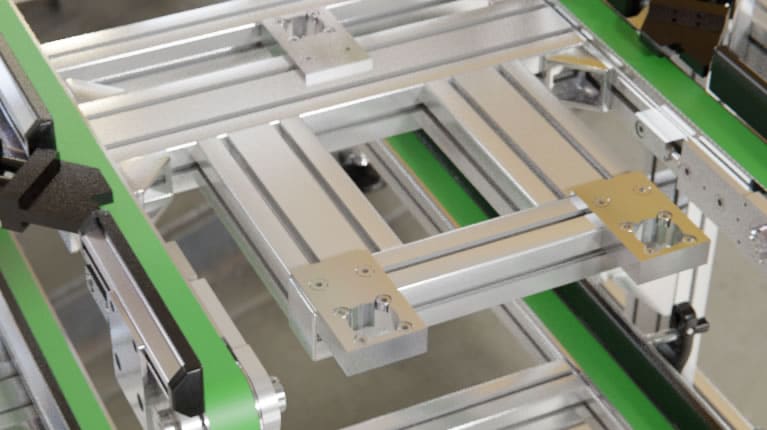

Pallet transfer system

This modular system is designed to effectively respond to the changing demands of the market. It facilitates installation, maintenance, and reconfiguration, allowing for quick expansions or modifications. Notable for improving productivity and reducing costs, it is an ideal solution for pallet handling in any industrial environment.

Accessories

Alusic provides a wide range of accessories designed to complement and optimize transportation systems. These include side containment guides, sliding profiles, and supports for side guides, among others, ensuring that each system fits perfectly with the specific transportation and material handling needs of customers.

Alusic’s conveyor belts are versatile solutions designed to adapt to a variety of industrial applications. Available in different series, each with specific features:

- Series 20: 20 mm diameter roller, ideal for light operations.

- Series 30: 30 mm diameter roller, for medium loads.

- Series 50 and 1000 Monoviga: 50 mm diameter roller, suitable for heavier loads.

- Series 95: 95 mm diameter roller, for the most demanding applications.

The Series 830 is specially designed to handle changes in slope within transport lines. With three basic structures (831, 832, and 833), this system allows for flexible and adaptable configurations, incorporating accessories such as hoppers and ramps to optimize transport in environments with height variations.

Alusic offers hinged belt conveyors with five different chain widths, ranging from 82.5 mm to 304.8 mm, available in both plastic and steel. These systems are ideal for applications that require durability and flexibility, with curves available as standard for the smaller models, facilitating integration in compact spaces.

Alusic’s modular chain conveyors feature plastic chains in two widths: 152 mm and 250 mm. These systems have composable beams and offer standard 90° and 180° curves, making them extremely flexible to fit any production layout.

This modular system is designed to effectively respond to the changing demands of the market. It facilitates installation, maintenance, and reconfiguration, allowing for quick expansions or modifications. Notable for improving productivity and reducing costs, it is an ideal solution for pallet handling in any industrial environment.

Alusic provides a wide range of accessories designed to complement and optimize transportation systems. These include side containment guides, sliding profiles, and supports for side guides, among others, ensuring that each system fits perfectly with the specific transportation and material handling needs of customers.

Discover cutting-edge transportation solutions with Sitalu

At Sitalu, we are committed to excellence and innovation, offering advanced modular transport solutions from the leading brands Alusic and Modu. If you are looking to optimize and automate your industrial processes with efficient and adaptable transport systems, contact us today. Our expert team is ready to help you select the perfect system that fits your specific needs and improve your production line.