Industrial transportation systems: key for efficient logistics

In today’s industrial environment, industrial conveying systems are critical to ensure the efficient to ensure the efficient movement of materials and products through the various stages of production.

These systems not only optimize internal factory logistics, but also play a crucial role in reducing costs and increasing productivity.

In this context, customization of conveyor systems has become a necessity to adapt to particular specifications and demands. to adapt to the particular specifications and demands of each industrial sector, thus ensuring optimum performance and increased operational efficiency.

Table of Contents

Customization of conveying systems: adapting to the needs of each industry

Customization of industrial conveyor systems is essential to meet the specific challenges of each industry. At Operber, we understand that each industry has its own particularities, so we offer tailor-made solutions that fit each customer’s unique needs. From food to automotive, pharmaceuticals to packaging, our conveyor systems are designed to improve logistical efficiency by adapting to different types of products, spaces and operational requirements.

Flexible conveying systems: versatility and efficiency on the move

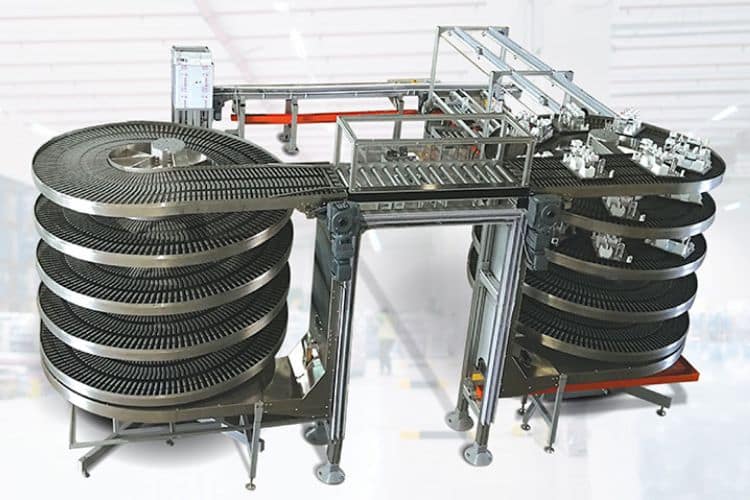

Flexible conveyor systems are essential in industries where adaptability and the ability to quickly modify production lines are critical. These systems are designed to handle frequent changes in industrial layout, allowing product flow to remain efficient regardless of the complexity of the route.

At Operber, we have implemented flexible transportation solutions in sectors such as food and automotive, where production lines need to continuously adapt to new demands and processes. For example, our systems allow the integration of tight curves and changes in heightWe use materials such as stainless steel and anodized aluminum to ensure the durability and resistance of the system, even in demanding working environments. In addition, we use materials such as stainless steel and anodized aluminum to ensure the durability and resistance of the system, even in demanding work environments.

These systems not only improve operational efficiency by reducing line changeover times, but also contribute to lower operating costs by minimizing production interruptions. Design flexibility allows Operber’s customers to adjust their conveyor line according to specific product needs, resulting in smoother and more effective internal logistics.

Roller conveyor systems: efficiency in load handling

Roller conveyor systems are a classic and highly efficient solution for product handling in industrial environments. These systems are especially suitable for the movement of heavy and bulky loads, such as boxes, pallets, or containers. At Operber, we design and manufacture roller conveyor systems adapted to the specific needs of each customer adapted to the specific needs of each customer, guaranteeing a continuous and safe work flow.

Rollers can be motorized or non-driven, depending on the needs of the production process. Motorized systems allow precise control of product speed and direction, which is crucial in automated production lines where synchronization is key. On the other hand, non-motorized rollers are used in processes where product movement can be managed by gravity or manual intervention.

A prime example of our installations is in the logistics industry, where roller systems are critical to the efficient movement of packages. roller systems are essential for the efficient movement of packages. in distribution centers. We have implemented solutions that include rollers with integrated sensors, capable of detecting the presence of a product and activating the next section of the line, thus optimizing the flow and reducing the need for manual intervention.

These systems are also versatile in terms of configuration, allowing the incorporation of diverters and automatic transfers that facilitate the organization and routing of products to different production lines or storage areas.

Flexible conveying systems: adaptability for complex layouts

Flexible conveyor systems are an ideal solution for industrial facilities where space is limited. industrial facilities where space is limited or where the production layout requires a high degree of adaptability. At Operber, we understand that each facility is unique, so our flexible conveying systems are designed to adapt to the specific conditions of each customer, enabling the efficient movement of products through complex trajectories ..

These systems are characterized by their ability to make tight turns, elevation changes, and transitions between different levels of the plant, without compromising the speed or stability of the conveyed product. This flexibility is particularly valuable in industries such as food and pharmaceuticalwhere space is often at a premium and processes require a constant and controlled flow of materials.

One of the product highlights in this category is the modular flexible chain conveyor, which allows highly flexible modular chain conveyor, which allows for highly customized configurations.. These conveyors can adapt to changes in production without significant reconfiguration, making them an economical and efficient option for growing companies or companies with constantly evolving processes.

In addition, our flexible conveying systems are designed to be compatible with a wide range of products, from small individual parts to large containers, making them suitable for multiple applications within the same facility. This versatility not only improves operational efficiency, but also reduces downtime and costs associated with equipment reconfiguration.

Roller conveyor systems: efficiency in load handling

Roller conveyor systems are essential in operations where the handling of heavy or bulky loads is required, such as in the automotive, logistics and distribution sectors. At Operber, we offer roller conveyors that adapt to different needs, from the transport of boxes to the handling of pallets.from the transport of boxes to the handling of pallets.

These systems allow smooth and controlled movement of products, reducing manual effort and improving operational efficiency. Our roller conveyors can be configured with motorized or gravity drive, depending on customer requirements, and are ideal for integration into automated production lines.

Customized solutions for every logistic need

At Operber, we understand that each company has unique needs in terms of its industrial transportation systems. Therefore, we specialize in offering customized solutions that optimize internal logistics, improving productivity and reducing costs. Whether through flexible conveyor systems, roller conveyors or any other solution, our goal is to provide the infrastructure that allows our customers to achieve their goals with greater efficiency and safety.

Related articles: